Innovations in Cold Chain Management for Exporting Fruits and Vegetables

Enhancing Efficiency with Technology

In recent years, the cold chain management industry has witnessed significant innovations, particularly in the export of fruits and vegetables. Maintaining the quality and freshness of these perishable items is critical, as it directly impacts their market value. One of the key advancements is the integration of Internet of Things (IoT) technology, which allows for real-time monitoring and control of environmental conditions during transit.

By utilizing IoT sensors, exporters can continuously track temperature, humidity, and other vital parameters. This data is then transmitted to a centralized system, enabling operators to make immediate adjustments when deviations occur. This technological advancement not only ensures product quality but also minimizes wastage and boosts overall efficiency in the supply chain.

Revolutionizing Packaging Solutions

Packaging plays a crucial role in cold chain management, and recent innovations have introduced revolutionary solutions. Advanced packaging materials now offer enhanced insulation properties, keeping fruits and vegetables fresh for extended periods. Moreover, these materials are designed to be environmentally sustainable, aligning with global efforts to reduce carbon footprints.

Another noteworthy development is the use of active packaging, which incorporates elements that interact with the produce to extend shelf life. For example, ethylene absorbers are used to slow down ripening processes, while antimicrobial packaging helps prevent spoilage by inhibiting bacterial growth. These innovative solutions are transforming how exporters approach packaging, ensuring that products arrive at their destination in optimal condition.

The Role of Artificial Intelligence

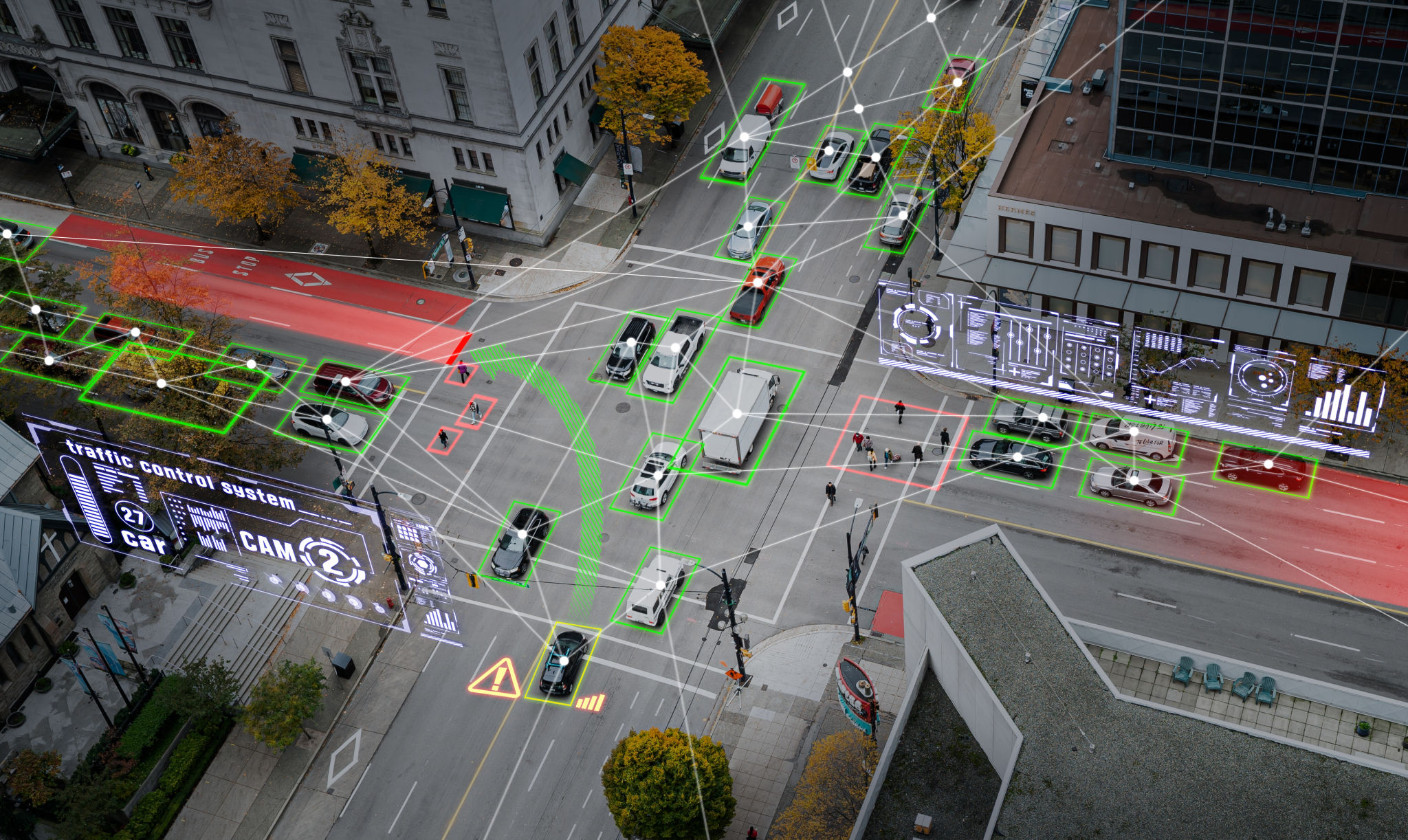

Artificial Intelligence (AI) is another game-changer in cold chain management. AI-powered algorithms can predict potential issues in the supply chain and suggest preemptive measures to mitigate risks. By analyzing historical data and identifying patterns, AI systems can optimize routing and scheduling, ensuring efficient delivery despite unforeseen challenges.

AI also enhances inventory management by forecasting demand accurately. This predictive capability helps exporters maintain optimal stock levels, reducing overproduction and minimizing waste. As AI technology continues to evolve, its applications in cold chain management are expected to expand further, offering even greater efficiencies.

Adoption of Blockchain Technology

Blockchain technology is increasingly being adopted to enhance transparency and traceability in the cold chain process. By providing a decentralized ledger of all transactions and movements, blockchain ensures that every party involved has access to an immutable record of the product's journey from farm to table.

This transparency builds trust among stakeholders, including consumers who demand assurance about the origin and handling of their food products. Blockchain also helps in quickly identifying and addressing any safety concerns, such as contamination or spoilage, thus safeguarding public health.

Implementing Renewable Energy Solutions

As sustainability becomes a critical focus across industries, renewable energy solutions are being increasingly integrated into cold chain operations. Solar-powered refrigeration units and energy-efficient cooling systems are being deployed to reduce reliance on fossil fuels and lower operational costs.

This shift towards green energy not only supports environmental goals but also enhances the resilience of the supply chain by reducing dependency on traditional power sources. As the industry continues to innovate, these renewable solutions will play a pivotal role in shaping a sustainable future for cold chain management.